- Security Business

- Metal Detector

It wasn't just about improving safety within the park! Network integration simultaneously reduced wait times and boosted operational efficiency.

Major Theme Park Business

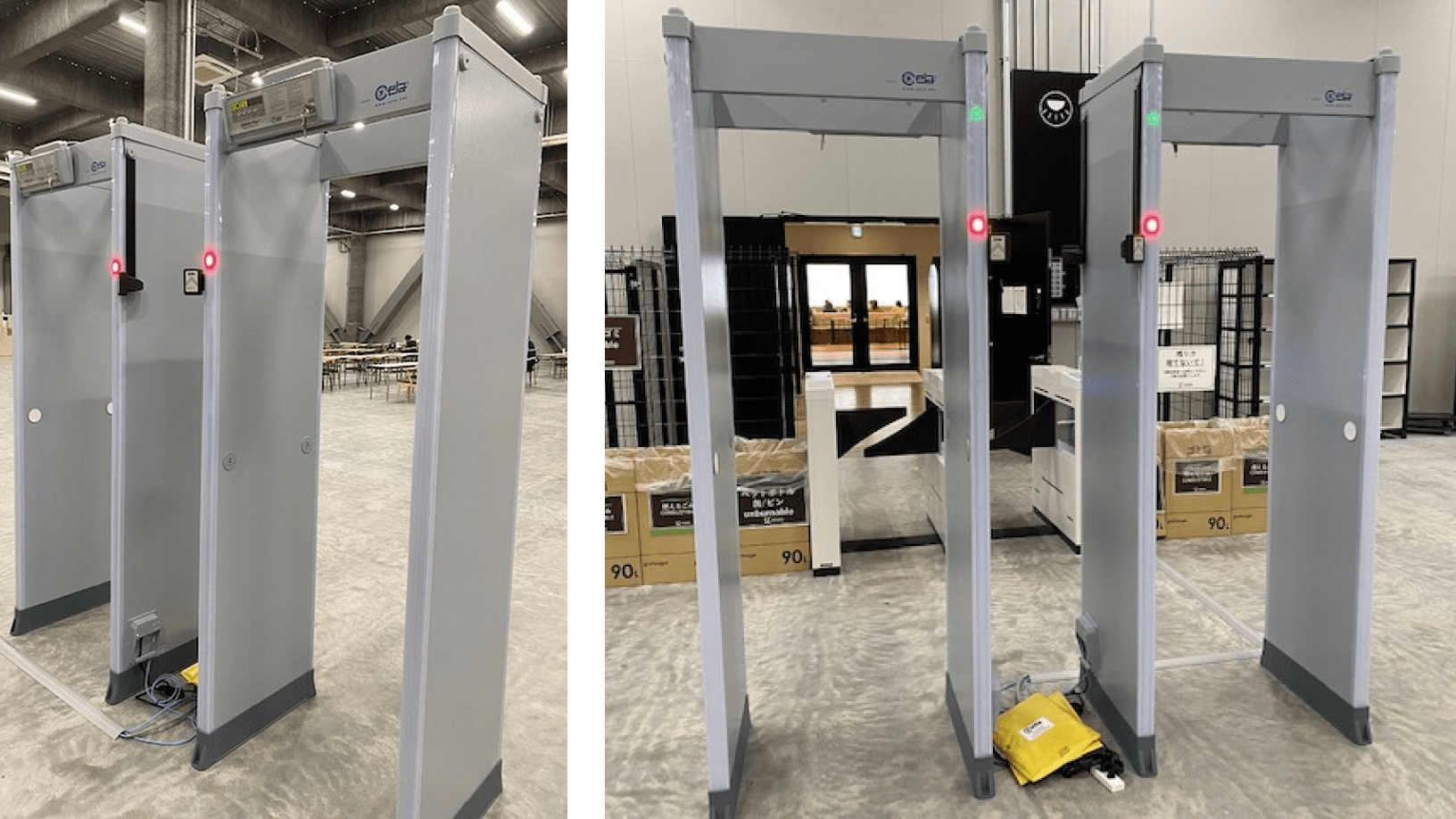

Installation Image at Entrance Gate

In response to the increase in the number of visitors to international events and the tightening of national security guidelines, our gate-type metal detectors were installed in a major theme park facility. By combining the screening of guests themselves with the centralized management of a network of devices, the accuracy and speed of inspection were greatly improved. This is a successful example of reducing the burden on both guests and crew members and improving customer satisfaction.

Challenges

- Guest screening was not conducted at entry, with only visual inspection of hand luggage

- Visual inspection was time-consuming and low in accuracy, placing a significant burden on guests and crew

- False alarms and throughput differences between devices were reducing operational efficiency

- Response to national security enhancement guidelines was required

Solution

- Permanent installation of walk-through metal detectors to screen guests

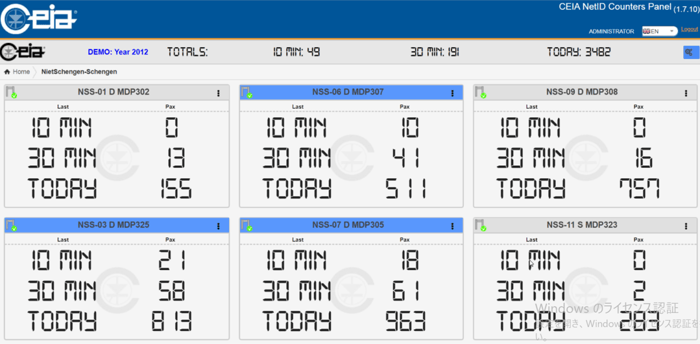

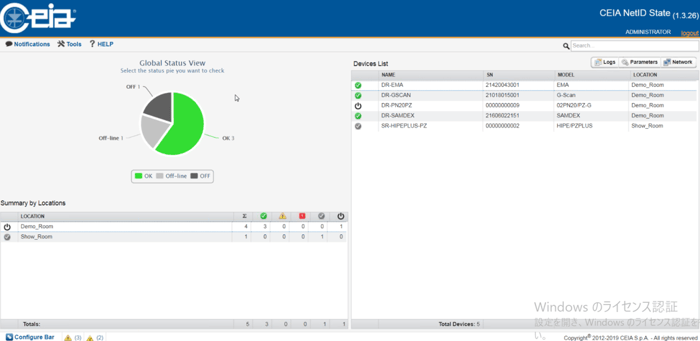

- Centralized network management of devices to monitor operational status in real-time

- Visualization and training of crew operations using camera footage and passage data

- Optimization of the number of operating units based on congestion data

Results

- Security level improved, reducing the risk of missing dangerous items

- Entry speed improved, reducing wait times and stress

- Overall throughput improved through standardization of crew operations

- Operational data obtained, contributing to continuous improvement and enhanced customer satisfaction

- Utilization of data acquisition for marketing purposes

Q: How did you come to introduce the system?

In the past, we only visually inspected baggage and did not screen guests themselves, which was time-consuming, labor-intensive, and of limited accuracy. In addition, opening a guest's personal belongings to check them was a burden on the crew in terms of privacy and psychological burden.

In order to investigate the introduction of non-contact screening of guests' personal belongings, we conducted a parallel demonstration test at the site and compared devices from multiple manufacturers. As a result, it was found that there were significant differences in false alarm rates and throughput among the devices, leading to the adoption of our devices, which excel in detection accuracy and operability. Furthermore, the centralized management through networking made it possible to standardize operations and make real-time improvements, which was a deciding factor in our decision to introduce the system.

Q: What were your honest impressions of the demonstration experiment?

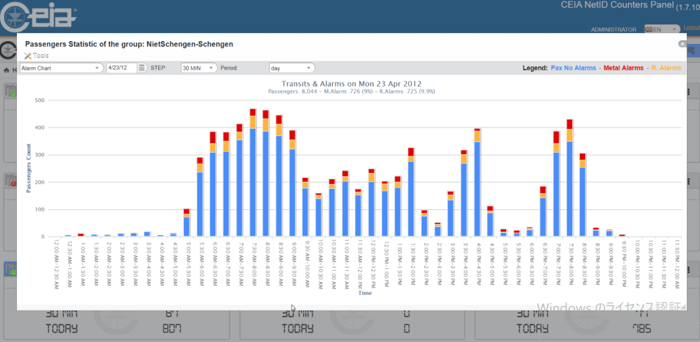

During the side-by-side experiment on site, we were honestly surprised at the large difference in the false alarm rate and the number of people passing through each device, even under the same security conditions. In particular, devices with many false alarms significantly reduced throughput, resulting in increased waiting time and crew workload. Since the proposed equipment had fewer false alarms and faster transit speeds, as well as easy data acquisition via the network, we could clearly see room for operational improvement. Through the experiment, we confirmed once again that both "equipment performance" and "operation methods" are important.

Simultaneous improvement of "safety," "efficiency," and "satisfaction" realized through detection accuracy and data utilization

In addition to ensuring safety, the introduction of the system has had a multifaceted effect, improving the speed of entry, reducing the workload of crews, and even increasing customer satisfaction. Here, we will take an in-depth look at some of the specific results.

- Quantitative Improvement of Safety Level

The risk of missing hazardous materials has been reduced by improving detection accuracy. Compared to operations centered on visual inspections, the reliability of inspections has increased.

- Throughput Improvement Mechanism

CEIA's unique networking and centralized management functions made it possible to collect real-time data on the number of people passing through, and identified cases where the cause of low throughput was not "equipment performance" but "crew guidance methods. For example, in a case where 300 people passed through a metal detector every 30 minutes, but only 230 people passed through this machine, detailed analysis of the camera mounted on the metal detector revealed a difference in the method of guiding guests in line for screening and the method of screening, and revealed a problem on the crew side. It was discovered that there was a problem on the crew side. By sharing and educating everyone on the superior crew methods, the number of people passing through all equipment was uniformly improved.

- Operational Cost and Operation Optimization

Visualization of congested times and congested areas made it possible to increase the number of units in operation during necessary times and reduce the number of units during off-peak hours. Reduced unnecessary operations and optimized allocation of human resources.

- Customer satisfaction and brand value

Guest satisfaction increased due to shorter waiting time and smoother inspections. Improved safety leads to a sense of security for visitors, and contributes to the enhancement of the theme park's brand value.

- Marketing applications

The acquired data on the number of people passing through and congestion trends can be used to understand visitor trends and can be utilized as a marketing measure.

Conclusion

The introduction of the gate-type metal detector and integrated network management proposed by the company enabled a departure from conventional visual inspections, improving inspection accuracy and speed of entry, and reducing the burden on both crew and guests at the same time. Not only that, but data-driven operational improvements have also led to overall throughput, customer satisfaction, and marketing utilization. This is a successful case study of the establishment of an efficient and secure admission management system, not to mention the improvement of safety in the park.

Product Introduction

PMD2Plus Cylinder type, NetID system

*CEIA Metal Detectors & Body Scanner Page is here

Related Content